-

Specifications

-

Standard/Optional Equipment

Maximum Power

74hp

Maximum Torque

221lb-ft @ 1600 rpm

Rated Speed

2200-2400 rpm

Minimum Power

67hp

Emissions

UN ECE R96 Stage IIIA, Brazil MAR-1

Engine Configuration

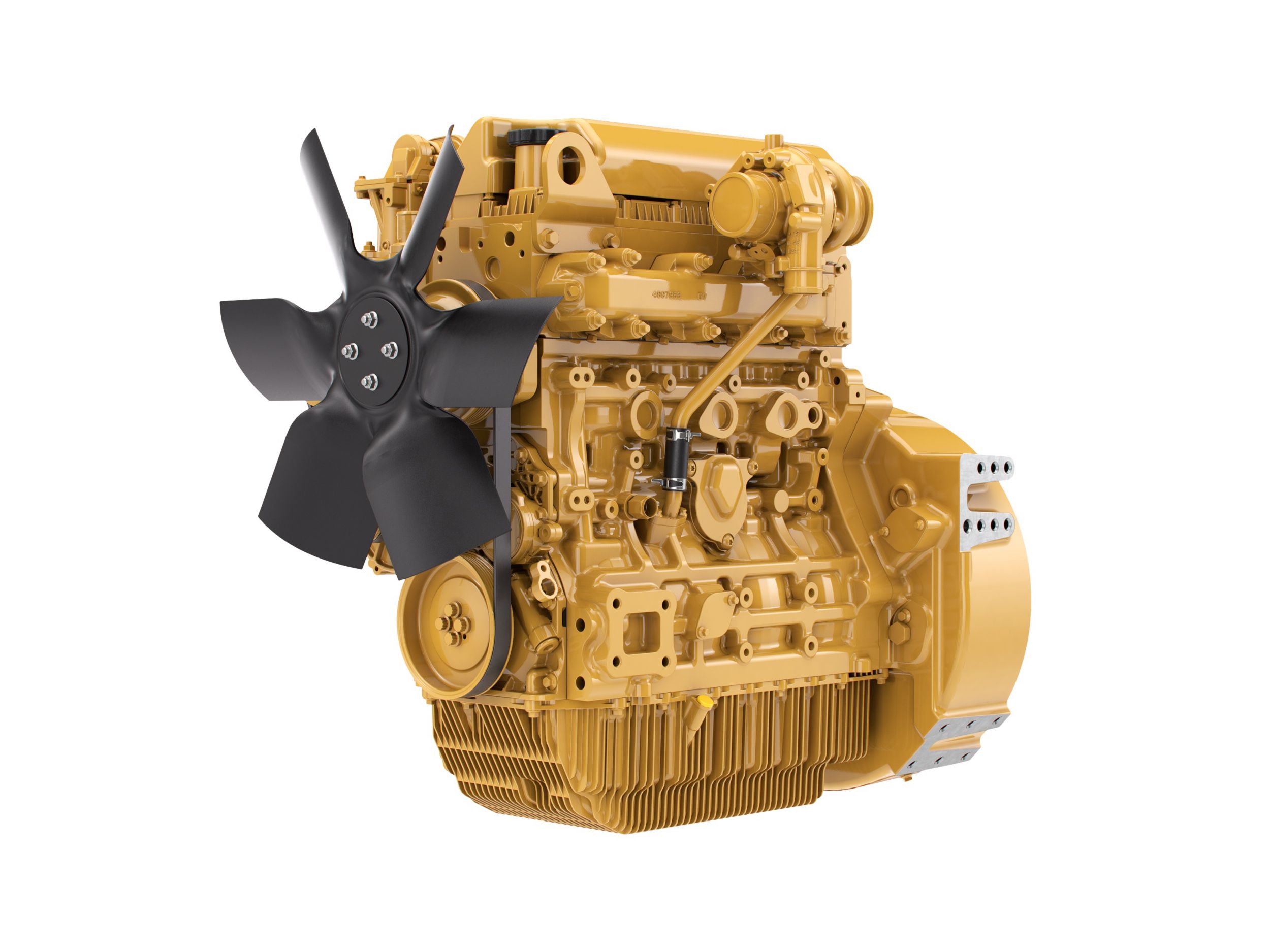

Inline 4, 4-Stroke-Cycle Diesel

Bore

3.5in

Stroke

4.3in

Displacement

171in³

Compression Ratio

17.0:1

Aspiration

Turbocharged (T) and Turbocharged Aftercooled (TA)

Combustion System

Direct Injection

Rotation from Flywheel End

Counterclockwise

Aftertreatment

-

Length

24.9in

Width

21.2in

Height

30.9in

Weight - Net Dry - Basic Operating Engine Without Optional Attachments

705lb

Air Inlet System

Induction manifolds

Exhaust manifolds

Control System

Starter motor (12V or 24V)

Alternator (12V or 24V)

Electronic Control Unit (chassis mounted)

Engine control sensors and robust wiring harness

Data interface via CANbus J1939

Flywheels and Flywheel Housing

Flywheel housings – SAE 3 or SAE 4

Choice of flywheel to match industry common hydraulic pumps and transmissions

Side PTO with SAE A or SAE B interface

Fuel System

Fuel filter – preconnected but chassis mounted

With water sensor

Lube System

Lubricating oil filters

High incline oil pan – 35° continuous in all directions

General

Cold start capability to -20° C (-4° F) with standard equipment

Paint: Caterpillar yellow, with optional colors available at request

ALL

Air Inlet System

Induction manifolds

Exhaust manifolds

Control System

Starter motor (12V or 24V)

Alternator (12V or 24V)

Electronic Control Unit (chassis mounted)

Engine control sensors and robust wiring harness

Data interface via CANbus J1939

Flywheels and Flywheel Housing

Flywheel housings – SAE 3 or SAE 4

Choice of flywheel to match industry common hydraulic pumps and transmissions

Side PTO with SAE A or SAE B interface

Fuel System

Fuel filter – preconnected but chassis mounted

With water sensor

Lube System

Lubricating oil filters

High incline oil pan – 35° continuous in all directions

General

Cold start capability to -20° C (-4° F) with standard equipment

Paint: Caterpillar yellow, with optional colors available at request