-

Specifications

-

Standard/Optional Equipment

Maximum Power

111.3hp

Maximum Torque

308lb-ft @ 1400 rpm

Rated Speed

2200-2400 rpm

Minimum Power

72.4hp

Emissions

UN ECE R96 Stage IIIA

Engine Configuration

Inline 4, 4-Stroke-Cycle Diesel

Bore

4.1in

Stroke

5in

Displacement

269in³

Compression Ratio

18.2:1

Aspiration

Naturally Aspirated (NA), Turbocharged (T) or Turbocharged Aftercooled (TA)

Combustion System

Direct Injection

Rotation from Flywheel End

Counterclockwise

Aftertreatment

-

Length

26.1in

Width

23.7in

Height

30.5in

Weight - Net Dry - Basic Operating Engine Without Optional Attachments

674.6lb

Air Inlet System

Inlet manifold with choice of inlets.

Control System

Alternator

Starter motor

Control Panel

Glow plug starting aid

Cooling System

Top tank temperature 108° C (226° F) as standard to minimize cooling pack size

50:50 water glycol mix

Flywheels and Flywheel Housing

SAE No. 3 flywheel housing

Flywheel and starter rings

Fuel System

Fuel filter positions

Lube System

Lubricating oil filters and breathers

Oil filter positions

Lube oil sump

Power Take Off

SAE B Power Take Off (PTO)

General

Timing case and gear-driven auxiliaries

Belt-driven auxiliaries

Engine mountings

Gauges

Displays

Power and torque curve tailoring

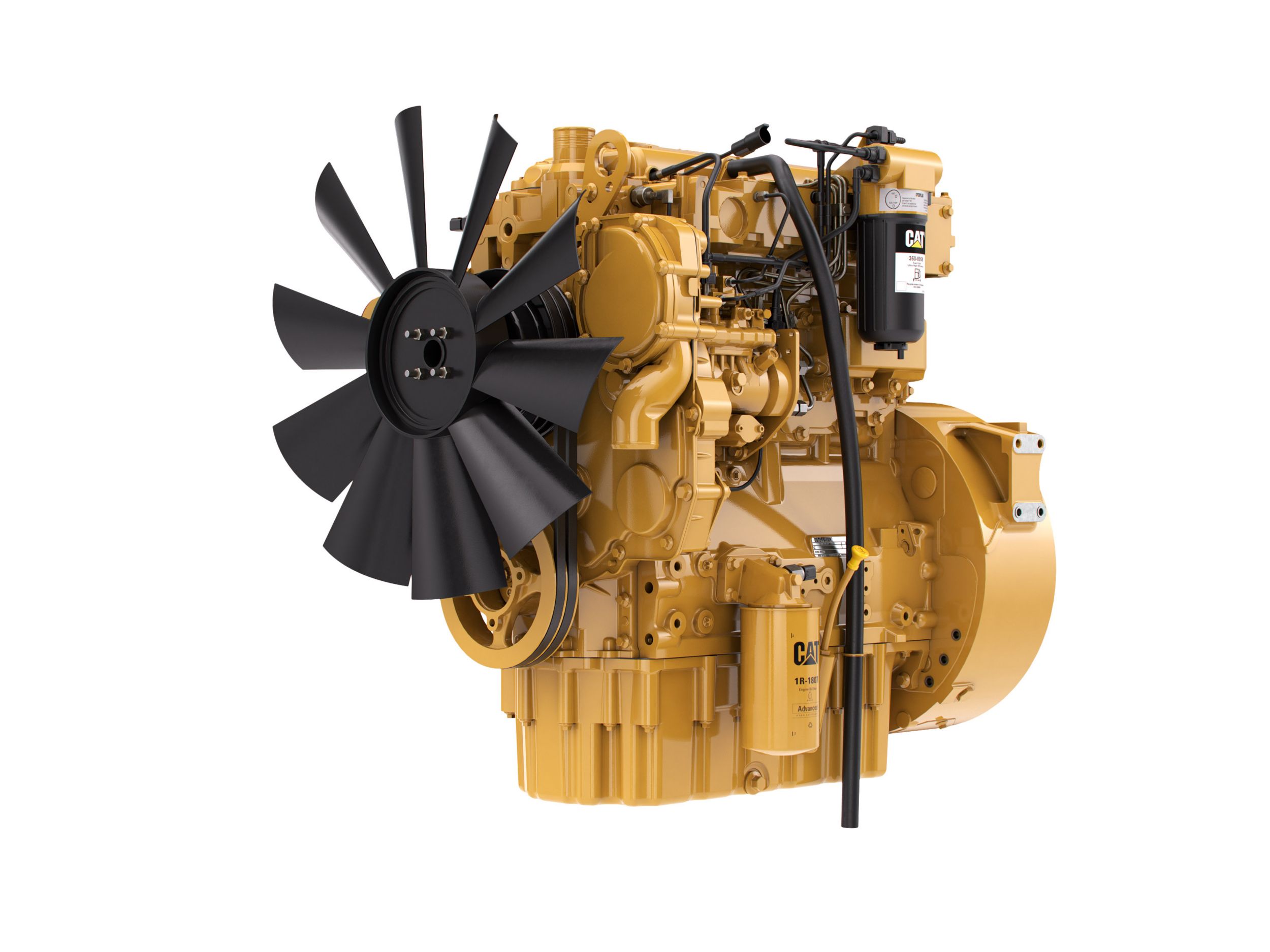

Paint: Caterpillar yellow, with optional colors available at request

ALL

Air Inlet System

Inlet manifold with choice of inlets.

Control System

Alternator

Starter motor

Control Panel

Glow plug starting aid

Cooling System

Top tank temperature 108° C (226° F) as standard to minimize cooling pack size

50:50 water glycol mix

Flywheels and Flywheel Housing

SAE No. 3 flywheel housing

Flywheel and starter rings

Fuel System

Fuel filter positions

Lube System

Lubricating oil filters and breathers

Oil filter positions

Lube oil sump

Power Take Off

SAE B Power Take Off (PTO)

General

Timing case and gear-driven auxiliaries

Belt-driven auxiliaries

Engine mountings

Gauges

Displays

Power and torque curve tailoring

Paint: Caterpillar yellow, with optional colors available at request