-

Specifications

-

Standard/Optional Equipment

- Catalog

Maximum Power

275hp

Maximum Torque

774lb-ft @ 1400 rpm

Rated Speed

116-205 bkW/156-275 bhp @ 2200 rpm, 129 bkW/173 bhp @ 2500 rpm

Minimum Power

156hp

Emissions

China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA

Engine Configuration

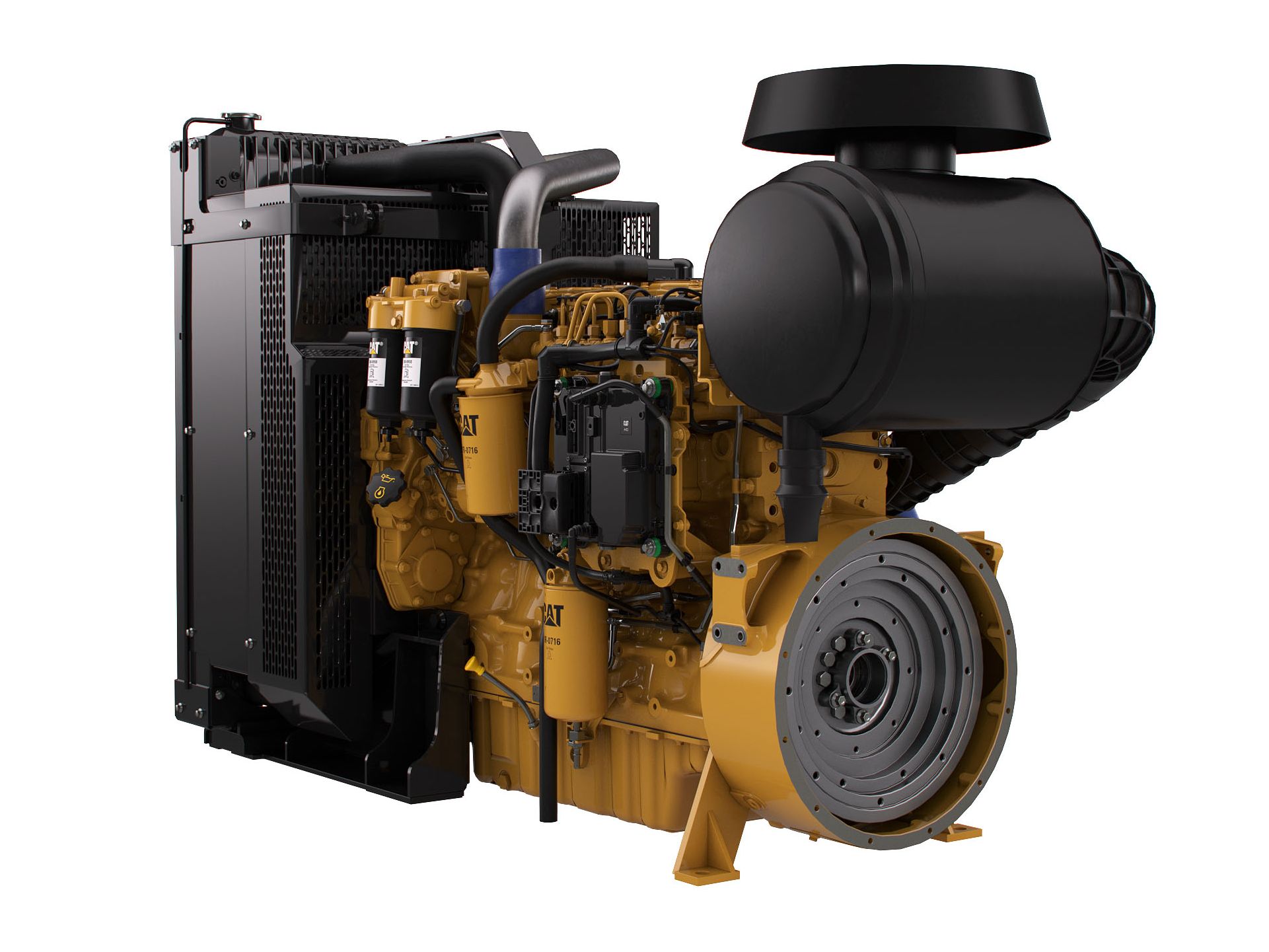

Inline 6, 4-Stroke-Cycle Diesel

Bore

4.1in

Stroke

5.3in

Displacement

427.7in³

Compression Ratio

16.8:1

Aspiration

Turbocharged Aftercooled (TA)

Rotation from Flywheel End

Counterclockwise

Aftertreatment

-

Length

68in

Width

31in

Height

44.8in

Weight

1737lb

Air Inlet

Standard air cleaners

Control System

Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

Cooling System

Top tank temperature 108° C (226° F) as standard to minimize cooling pack size

50:50 water glycol mix

Cooling system designed for operation in 48 C (118 F) ambient.

Flywheels and Flywheel Housing

Wide choice of drivetrain interfaces, including SAE No. 1, SAE No. 2, and SAE No. 3 configurations

Fuel System

Electronic high pressure common rail

ACERT Technology

Innovative filter design to ensure maximum protection of the engine

Lube System

Wide choice of sumps for different applications

Power Take Off

SAE A or SAE B flanges on left-hand side. Right-hand side twin PTO also available. Engine power can also be taken from the front of the engine on some applications.

General

Paint: Caterpillar yellow

ALL

Air Inlet

Standard air cleaners

Control System

Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments

Flexible and configurable software features and well-supported SAE J1939 CAN bus enables highly integrated machines

Cooling System

Top tank temperature 108° C (226° F) as standard to minimize cooling pack size

50:50 water glycol mix

Cooling system designed for operation in 48 C (118 F) ambient.

Flywheels and Flywheel Housing

Wide choice of drivetrain interfaces, including SAE No. 1, SAE No. 2, and SAE No. 3 configurations

Fuel System

Electronic high pressure common rail

ACERT Technology

Innovative filter design to ensure maximum protection of the engine

Lube System

Wide choice of sumps for different applications

Power Take Off

SAE A or SAE B flanges on left-hand side. Right-hand side twin PTO also available. Engine power can also be taken from the front of the engine on some applications.

General

Paint: Caterpillar yellow