-

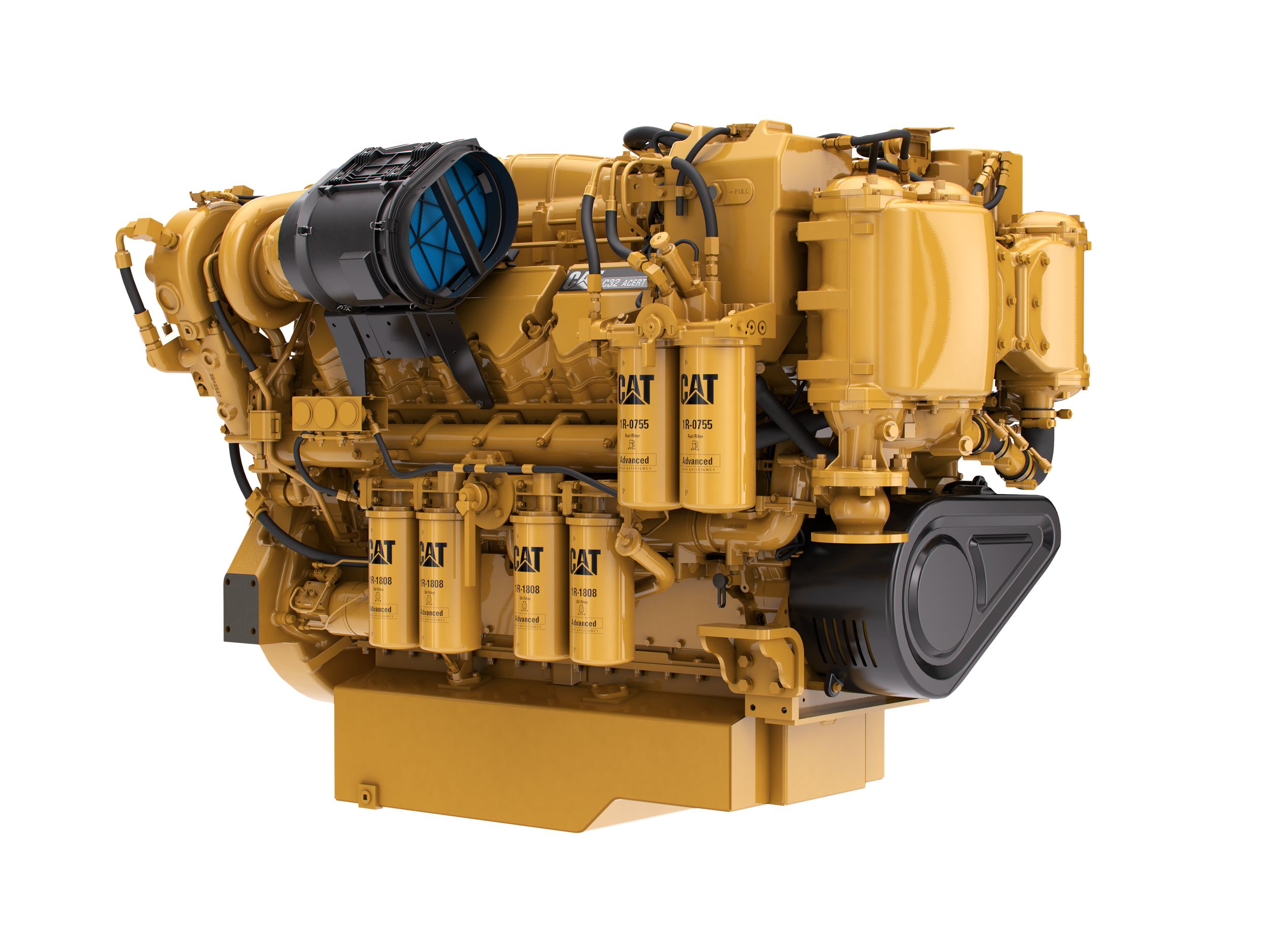

Specifications

-

Standard/Optional Equipment

- Catalog

Power Range

660 - 1600 bhp (492 - 1193 bkW)

Speed Range

1600 - 2300 rpm

Emissions

U.S. EPA Tier 3/ Tier 4, IMO II/III, EU Stage V

Aspiration

Twin Turbocharged Aspiration

Bore

5.71in

Stroke

6.38in

Displacement

1959in³

Rotation from Flywheel End

Counterclockwise

Configuration

V 12, 4-Stroke-Cycle Diesel

Maximum Height

62.5in

Minimum Length

77.8in

Minimum Height

60.9in

Maximum Width

60.17in

Maximum Length

83.5in

Minimum Width

60.17in

Air Inlet Systems

Air Inlet Cleaner

Air Inlet Adapter

Charging Systems

Battery Charger

Charging Alternators

Ammeter

Cooling System

Marine Gear/Transmission Oil Coolers

Connections

Exhaust System

Dual Elbow

Flexible Fitting

Dual Muffler

Muffler Spark Arresting

Flange

Fuel System

Water Separator

Instrumentation

OEM Wiring Harness

Engine to Engine Harness

Instrument Panels

Exhaust Temperature Sensors

Wiring Harness

Gauges

Transmission Sensors

Lube System

Transmission Oil Cooler

Manual Sump Pump

Duplex Oil Filters

Protection System

Fuel and Oil Shielding

Starting System

Air Starting Motor

Air Start Accessories

Electric Starting Motors - Single 24 Volt

Starting Aids

Battery Sets - 24 Volt - Dry

Dual Starting Motors (Electric and Air)

Packing

Engine Protective Cover

Export Packing

Storage Preservation

Mounting System

Front Support

Adapter Kits

Isolator Mounts

Power Take-Offs

Front Enclosed Clutches

Rear Hydraulic Pump Drive

GENERAL

Fumes Disposal

CONTROL SYSTEM

Instrument Panels

CATERPILLAR ALARM AND PROTECTION

Fuel and Oil Shielding

AIR INLET SYSTEM

Separate Circuit After-Cooled (SCAC)

Seawater After-Cooling (SWAC) System

Air cleaner

Turbochargers, jacket water cooled

Turbochargers inlet, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

Programmable Low Idle (550 - 750 rpm)

WOSR (Wide Operating Speed Range) available for - A, B, & C Ratings

Programmable High Idle Limit for WOSR Ratings

Electronic diagnostics and fault logging

Engine and transmission monitoring (speed, temperature, pressure)

Electronic fuel/air ratio control

Engine Protection Mode for extended ambient conditions

Torque Limiting functionality for WOSR ratings only

70-pin customer connector

Throttle Input signal options

COOLING SYSTEM

Separate Circuit After-Cooling (SCAC) for Heat Exchanged (HEX) & Keel cooled engines

Jacket Water (JW) and SCAC Heat Exchangers Shell & Tube for HEX cooled engines

SCAC pump, gear driven

Jacket water pump, gear driven

Sea water pump, bronze impeller, gear driven, for HEX cooled engines only

Sea water Pump & JW Heat Exchanger Connection: 76.2 mm (3in) ID Standard

Keel Connections: 76.2 mm (3in) ID Standard 4 Bolt ANSI Flange Connection

SCAC and JW shunt tanks for maintaining proper pump inlet pressures

Seawater After-Cooling (SWAC) System

EXHAUST SYSTEM

4 Bolt 130 mm (5.12 in) diameter flanged outlet

Water-cooled exhaust manifold & turbocharger

FLYWHEELS & FLYWHEEL HOUSINGS

SAE standard rotation (CCW facing exciter end)

Flywheel Housing: SAE No. 0, Flywheel: 18 inch, 136 teeth

FUEL SYSTEM

Duplex Fuel Filters, Spin-on, RH & LH service

Fuel connections size:Supply JIC 37 Deg -10 (7/8-14), Return JIC 37 Deg -8 (3/4-16)

Plate Type Fuel Cooler installed behind Aftercooler Shunt Tank

Fuel transfer pump, gear driven

Manual fuel priming pump

Hybrid fuel line design

LUBE SYSTEM

Simplex Oil Filters, RH or LH service

Deep sump oil pan

RH or LH service oil filler locations

RH or LH service dipstick

Oil pump, gear driven

MOUNTING SYSTEM

Front support - adjustable

POWER TAKE-OFFS

Front Poly-V groove pulley (Quantity 1) for auxiliary drives

GENERAL

Common electrical bonding point

Engine does not ship with zinc components

ALL

AIR INLET SYSTEM

Separate Circuit After-Cooled (SCAC)

Seawater After-Cooling (SWAC) System

Air cleaner

Turbochargers, jacket water cooled

Turbochargers inlet, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

Programmable Low Idle (550 - 750 rpm)

WOSR (Wide Operating Speed Range) available for - A, B, & C Ratings

Programmable High Idle Limit for WOSR Ratings

Electronic diagnostics and fault logging

Engine and transmission monitoring (speed, temperature, pressure)

Electronic fuel/air ratio control

Engine Protection Mode for extended ambient conditions

Torque Limiting functionality for WOSR ratings only

70-pin customer connector

Throttle Input signal options

COOLING SYSTEM

Separate Circuit After-Cooling (SCAC) for Heat Exchanged (HEX) & Keel cooled engines

Jacket Water (JW) and SCAC Heat Exchangers Shell & Tube for HEX cooled engines

SCAC pump, gear driven

Jacket water pump, gear driven

Sea water pump, bronze impeller, gear driven, for HEX cooled engines only

Sea water Pump & JW Heat Exchanger Connection: 76.2 mm (3in) ID Standard

Keel Connections: 76.2 mm (3in) ID Standard 4 Bolt ANSI Flange Connection

SCAC and JW shunt tanks for maintaining proper pump inlet pressures

Seawater After-Cooling (SWAC) System

EXHAUST SYSTEM

4 Bolt 130 mm (5.12 in) diameter flanged outlet

Water-cooled exhaust manifold & turbocharger

FLYWHEELS & FLYWHEEL HOUSINGS

SAE standard rotation (CCW facing exciter end)

Flywheel Housing: SAE No. 0, Flywheel: 18 inch, 136 teeth

FUEL SYSTEM

Duplex Fuel Filters, Spin-on, RH & LH service

Fuel connections size:Supply JIC 37 Deg -10 (7/8-14), Return JIC 37 Deg -8 (3/4-16)

Plate Type Fuel Cooler installed behind Aftercooler Shunt Tank

Fuel transfer pump, gear driven

Manual fuel priming pump

Hybrid fuel line design

LUBE SYSTEM

Simplex Oil Filters, RH or LH service

Deep sump oil pan

RH or LH service oil filler locations

RH or LH service dipstick

Oil pump, gear driven

MOUNTING SYSTEM

Front support - adjustable

POWER TAKE-OFFS

Front Poly-V groove pulley (Quantity 1) for auxiliary drives

GENERAL

Common electrical bonding point

Engine does not ship with zinc components

Optional Equipment

Air Inlet Systems

Air Inlet Cleaner

Air Inlet Adapter

Charging Systems

Battery Charger

Charging Alternators

Ammeter

Cooling System

Marine Gear/Transmission Oil Coolers

Connections

Exhaust System

Dual Elbow

Flexible Fitting

Dual Muffler

Muffler Spark Arresting

Flange

Fuel System

Water Separator

Instrumentation

OEM Wiring Harness

Engine to Engine Harness

Instrument Panels

Exhaust Temperature Sensors

Wiring Harness

Gauges

Transmission Sensors

Lube System

Transmission Oil Cooler

Manual Sump Pump

Duplex Oil Filters

Protection System

Fuel and Oil Shielding

Starting System

Air Starting Motor

Air Start Accessories

Electric Starting Motors - Single 24 Volt

Starting Aids

Battery Sets - 24 Volt - Dry

Dual Starting Motors (Electric and Air)

Packing

Engine Protective Cover

Export Packing

Storage Preservation

Mounting System

Front Support

Adapter Kits

Isolator Mounts

Power Take-Offs

Front Enclosed Clutches

Rear Hydraulic Pump Drive

GENERAL

Fumes Disposal

CONTROL SYSTEM

Instrument Panels

CATERPILLAR ALARM AND PROTECTION

Fuel and Oil Shielding