-

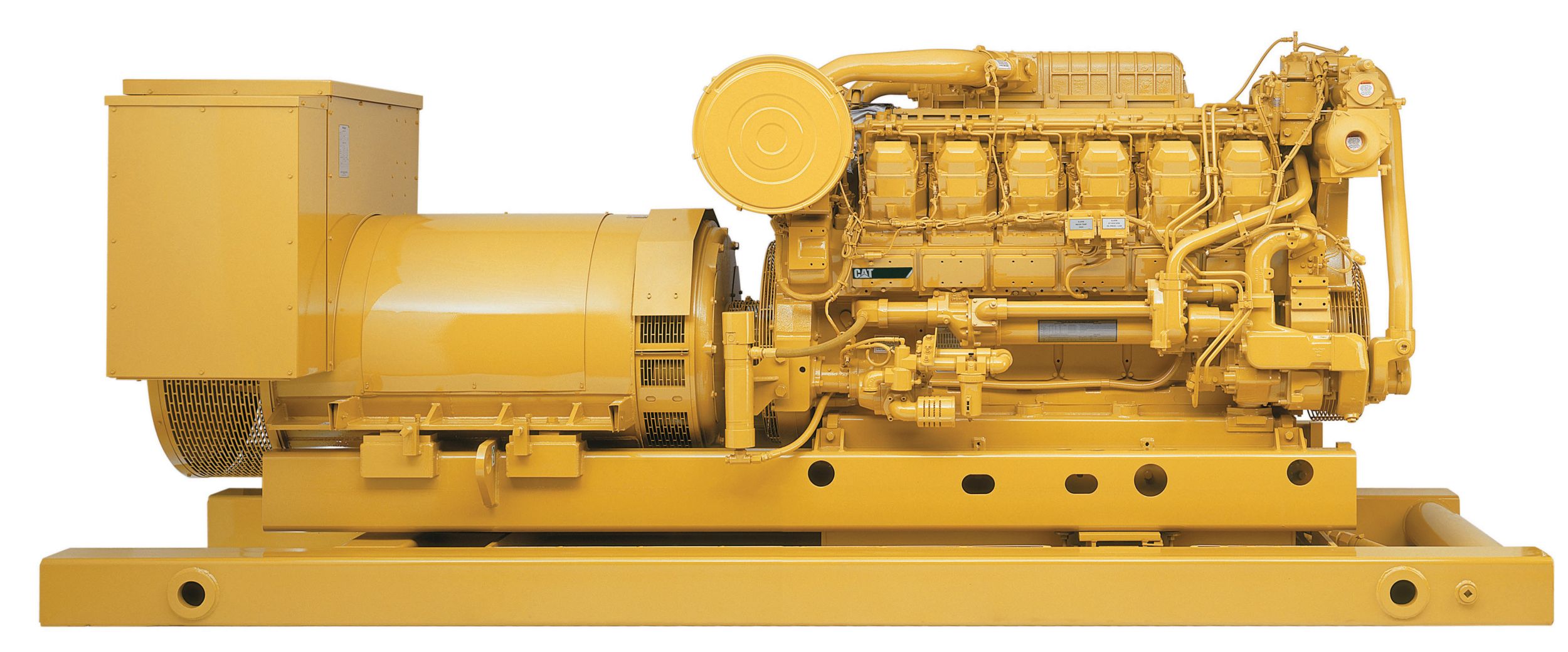

Specifications

-

Standard/Optional Equipment

- Catalog

Minimum Rating

1100kV·A

Maximum Rating

1943kV·A

Emissions

IMO Tier I

Weight

33014lb

Stroke

7.5in

Displacement

3175in³

Bore

6.7in

Oil Change Interval

1000h

Engine Control

ADEM A3

Aspiration

Turbocharged-Aftercooled

Fuel System

EUI

Height

86.9in

Length

190.6in

Width

78.3in

Cooling System - Engine

106gal (US)

Lube Oil System - Refill

84gal (US)

AIR INLET SYSTEM

Remote Air Inlet Adapters

CHARGING SYSTEM

Battery Chargers

Charging Alternators

CONTROL SYSTEM

Load Sharing module

Local speed throttle control

Direct rack control interface, 0-200 mA DC control

COOLING SYSTEM

Coolant level sensors

Connections

Air separator

EXHAUST SYSTEM

Flexible fittings

Elbows

Flanges

Flange and exhaust expanders

Mufflers

FUEL SYSTEM

Fuel Cooler

Primary fuel filter

Fuel filters

Duplex fuel filters

Fuel level switch

GENERATOR ATTACHMENTS

Air filter — generator

Bearing temperature detectors

Cable access box

Manual voltage control

INSTRUMENTATION

PL1000T Communication Module

PL1000E Communication Module

Customer Interface Box

Remote panel display

Remote cylinder temperature display

Exhaust temperature thermocouples

Discrete I/O module

Intake manifold temperature sensors

Oil temperature sensor

LUBE SYSTEM

Duplex oil filter

Bypass centrifugal oil filter

500-hour oil pan

Emergency lube oil connections

Oil level regulator

Prelube

Sump pump

MOUNTING SYSTEM

Vibration isolators

POWER TAKE-OFFS

Auxiliary drive shafts and pulleys

STARTING SYSTEM

Air or electric starting motor

Redundant start with select switch

PROTECTION SYSTEM

Spray shielding

Crankcase explosion relief valve

Metal particle detector

GENERAL

Jacket water heater

AIR INLET SYSTEM

Separate Circuit aftercooler core, corrosion resistant coated(air side)Air cleaner, regular dutyDual Turbochargers, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

Caterpillar A-III Electronic Engine Control, LHwith Electronic Unit Injector Fuel SystemRigid Wiring Harness(10 amp DC power required to drive Electronic Engine Control Module)

COOLING SYSTEM

Outlet controlled thermostat and housing, full opentemperature 92°C (198°F)

Jacket water pump, gear driven

Single water outlet connection, includes flange:143 mm (5.6")

Aftercooler fresh water cooling pump (SCAC), gear drivencentrifugal

SCAC pump circuit contains a thermostat to keep theaftercooler coolant from falling below 30°C (85°F)

EXHAUST SYSTEM

Dry gas tight exhaust manifolds with heat shieldsDual Turbochargers with watercooled bearings and heat shieldsExhaust outlet, vertical, 203 mm (8 in) round flanged outlet

FLYWHEELS & FLYWHEEL HOUSINGS

Flywheel, SAE No. 00, 183 teethFlywheel housing, SAE No. 00

FUEL SYSTEM

Fuel filter

Fuel transfer pump

Electronically Controlled Unit Injectors

Fuel priming pump, LH

Rigid fuel return line with customer connection point asbase of engine

INSTRUMENTATION

Overspeed shutdown notification light, Emergency stop notification light

Graphical Unit (Marine Power Display) for analog or digital displayof:

LUBE SYSTEM

Crankcase breather, top mounted

Oil cooler

Oil filter and dipstick, LH

Oil pump, gear-type

Oil pan drain valve, 2" NPT female connection

PROTECTION SYSTEM

A-III Electronic Monitoring System provides customer programmableengine de-ration strategies to protect against adverse operatingconditions

Emergency stop push button (located in Electronic Instrument Panel)Safety shutoff protection:

STARTING SYSTEM

Air starting motor, RH, 620 to 1034 kPa (90 to 150 psi),LH control

Air silencer

GENERAL

Paint, Caterpillar yellow, with black rails

Vibration damper and guard

Lifting eyes

Engine and generator, three-point mounted to sub-base

Lift provisions on base

Oil drain extension

Engine length drip pan

ALL

AIR INLET SYSTEM

Separate Circuit aftercooler core, corrosion resistant coated(air side)Air cleaner, regular dutyDual Turbochargers, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

Caterpillar A-III Electronic Engine Control, LHwith Electronic Unit Injector Fuel SystemRigid Wiring Harness(10 amp DC power required to drive Electronic Engine Control Module)

COOLING SYSTEM

Outlet controlled thermostat and housing, full opentemperature 92°C (198°F)

Jacket water pump, gear driven

Single water outlet connection, includes flange:143 mm (5.6")

Aftercooler fresh water cooling pump (SCAC), gear drivencentrifugal

SCAC pump circuit contains a thermostat to keep theaftercooler coolant from falling below 30°C (85°F)

EXHAUST SYSTEM

Dry gas tight exhaust manifolds with heat shieldsDual Turbochargers with watercooled bearings and heat shieldsExhaust outlet, vertical, 203 mm (8 in) round flanged outlet

FLYWHEELS & FLYWHEEL HOUSINGS

Flywheel, SAE No. 00, 183 teethFlywheel housing, SAE No. 00

FUEL SYSTEM

Fuel filter

Fuel transfer pump

Electronically Controlled Unit Injectors

Fuel priming pump, LH

Rigid fuel return line with customer connection point asbase of engine

INSTRUMENTATION

Overspeed shutdown notification light, Emergency stop notification light

Graphical Unit (Marine Power Display) for analog or digital displayof:

LUBE SYSTEM

Crankcase breather, top mounted

Oil cooler

Oil filter and dipstick, LH

Oil pump, gear-type

Oil pan drain valve, 2" NPT female connection

PROTECTION SYSTEM

A-III Electronic Monitoring System provides customer programmableengine de-ration strategies to protect against adverse operatingconditions

Emergency stop push button (located in Electronic Instrument Panel)Safety shutoff protection:

STARTING SYSTEM

Air starting motor, RH, 620 to 1034 kPa (90 to 150 psi),LH control

Air silencer

GENERAL

Paint, Caterpillar yellow, with black rails

Vibration damper and guard

Lifting eyes

Engine and generator, three-point mounted to sub-base

Lift provisions on base

Oil drain extension

Engine length drip pan

Optional Equipment

AIR INLET SYSTEM

Remote Air Inlet Adapters

CHARGING SYSTEM

Battery Chargers

Charging Alternators

CONTROL SYSTEM

Load Sharing module

Local speed throttle control

Direct rack control interface, 0-200 mA DC control

COOLING SYSTEM

Coolant level sensors

Connections

Air separator

EXHAUST SYSTEM

Flexible fittings

Elbows

Flanges

Flange and exhaust expanders

Mufflers

FUEL SYSTEM

Fuel Cooler

Primary fuel filter

Fuel filters

Duplex fuel filters

Fuel level switch

GENERATOR ATTACHMENTS

Air filter — generator

Bearing temperature detectors

Cable access box

Manual voltage control

INSTRUMENTATION

PL1000T Communication Module

PL1000E Communication Module

Customer Interface Box

Remote panel display

Remote cylinder temperature display

Exhaust temperature thermocouples

Discrete I/O module

Intake manifold temperature sensors

Oil temperature sensor

LUBE SYSTEM

Duplex oil filter

Bypass centrifugal oil filter

500-hour oil pan

Emergency lube oil connections

Oil level regulator

Prelube

Sump pump

MOUNTING SYSTEM

Vibration isolators

POWER TAKE-OFFS

Auxiliary drive shafts and pulleys

STARTING SYSTEM

Air or electric starting motor

Redundant start with select switch

PROTECTION SYSTEM

Spray shielding

Crankcase explosion relief valve

Metal particle detector

GENERAL

Jacket water heater