-

Specifications

-

Standard/Optional Equipment

- Catalog

Continuous Rating

4300 / 4000 ekW @1.0pf

Fuel Type

Natural Gas, Biogas, Coal Gas, Associated Gas, Synthesis Gas, Hydrogen Blend (to 25%)

Maximum Electrical Efficiency

44.1 / 43.8%

Maximum Standby Rating

4500 ekW

Frequency

50 / 60 Hz

RPM

1000 / 900 rpm

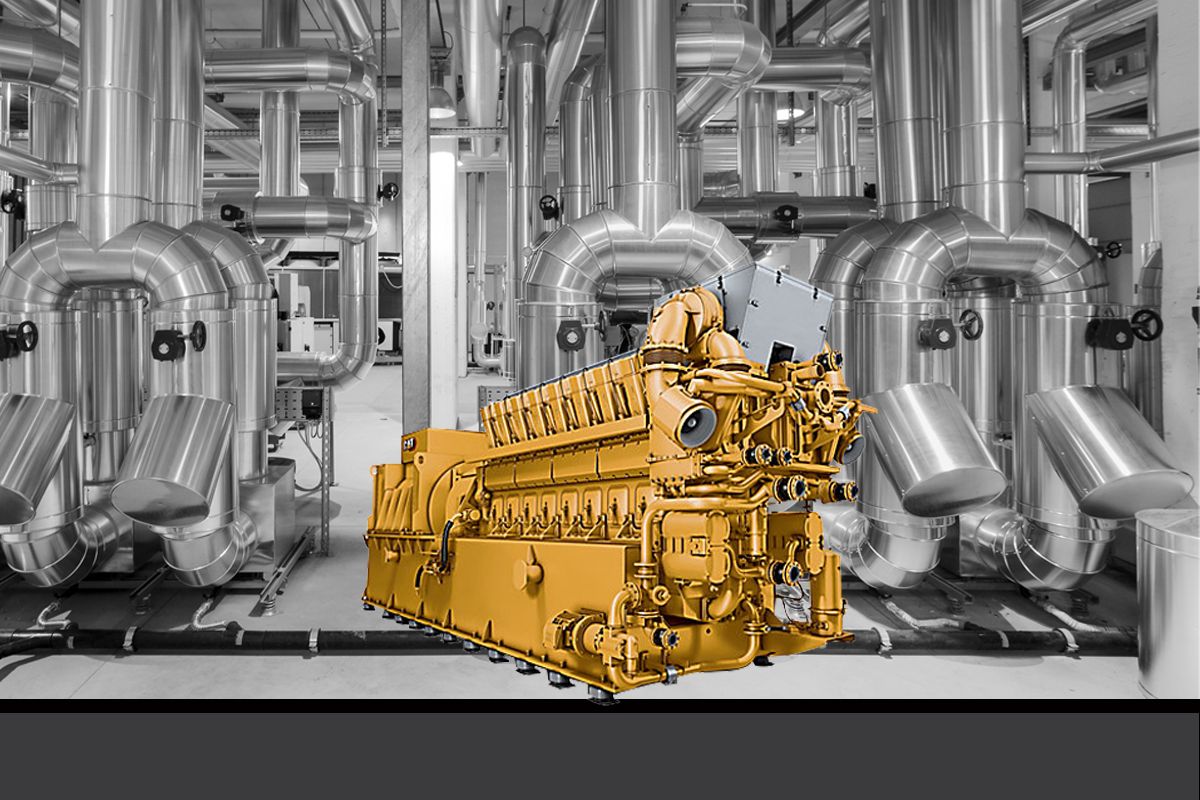

Engine Model

CG260-16

Displacement

16586in³

Aspiration

TA

Bore

10.2in

Stroke

12.6in

Length

371in

Width

110in

Height

133in

Dry Weight - Genset

117505lb

Cooling

CHP skid

Grid Code Compliance

50Hz: Germany, Belgium, Great Britain, Italy, Poland, and Netherlands

Air Inlet

One-element single-stage air cleaner with enclosure and sevice indicator

Turbocharger with a water-cooled bearing case for all cylinder

Control Panels

TEM (Total Electronic Management)

Cooling

flange connections for JW inlet and outlet

Jacket water and SCAC thermostats

Electrical jacket water and aftercooler coolant pump

Exhaust

Exhaust waste gate for the CG260-16

Closed crankcase ventilation system

Fuel system

Electronic fuel metering valve

Independently controlled cylinder monitoring and ignition system

Pre-chamber spark plugs

Generator

Busbar connections

Closed-coupled generator result in no torque transmission to the base frame

Reactive droop

3-phase sensing and KVAR/PF control

Grid code generator

Anti-condensation space heater

Winding temperature detectors

Starting/Charging

Compressed air engine start

General

Crankshaft vibration damper and guard

ALL

Air Inlet

One-element single-stage air cleaner with enclosure and sevice indicator

Turbocharger with a water-cooled bearing case for all cylinder

Control Panels

TEM (Total Electronic Management)

Cooling

flange connections for JW inlet and outlet

Jacket water and SCAC thermostats

Electrical jacket water and aftercooler coolant pump

Exhaust

Exhaust waste gate for the CG260-16

Closed crankcase ventilation system

Fuel system

Electronic fuel metering valve

Independently controlled cylinder monitoring and ignition system

Pre-chamber spark plugs

Generator

Busbar connections

Closed-coupled generator result in no torque transmission to the base frame

Reactive droop

3-phase sensing and KVAR/PF control

Grid code generator

Anti-condensation space heater

Winding temperature detectors

Starting/Charging

Compressed air engine start

General

Crankshaft vibration damper and guard

Optional Equipment

Cooling

CHP skid

Grid Code Compliance

50Hz: Germany, Belgium, Great Britain, Italy, Poland, and Netherlands